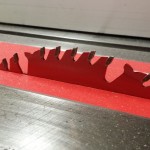

If you get to a point where your table saw blade isn’t cutting as well as it used to be, such as burning and leaving a rough surface behind, the blade may not be dull. The blade may simply need cleaning. What happens is you cut different materials, especially those with resins and glues in them, you will start to get pitch building up on the blade.

If you get to a point where your table saw blade isn’t cutting as well as it used to be, such as burning and leaving a rough surface behind, the blade may not be dull. The blade may simply need cleaning. What happens is you cut different materials, especially those with resins and glues in them, you will start to get pitch building up on the blade.

There are several products out there that will clean the blade well. The one that I have used is white vinegar. I put the blade in a shallow pan, and the poured enough of the white vinegar enough to cover the blade. I let it stay in the vinegar for 30-60 minutes. I don’t want to leave it in much longer than that as the vinegar will cause the blade to rust. I then used a paper towel to wipe down the blade. The pitch and residue wipes off easily. The vinegar is acidic, so I sprayed the blade down well in the kitchen sink. Note, do this when the wife is away! 🙂 After rinsing it off real well, I thoroughly dry the blade. Once dry, I put the blade back on the saw, and make a few test cuts. This serves two purposes. First it makes sure that the blade is completely dry. Second, the test cut will show that the blade is cutting proper again. If the blade is still cutting rough and burning the stock, it maybe time to get it sharpened. Most times cleaning the blade will be enough to get it cutting well again.

is acidic, so I sprayed the blade down well in the kitchen sink. Note, do this when the wife is away! 🙂 After rinsing it off real well, I thoroughly dry the blade. Once dry, I put the blade back on the saw, and make a few test cuts. This serves two purposes. First it makes sure that the blade is completely dry. Second, the test cut will show that the blade is cutting proper again. If the blade is still cutting rough and burning the stock, it maybe time to get it sharpened. Most times cleaning the blade will be enough to get it cutting well again.